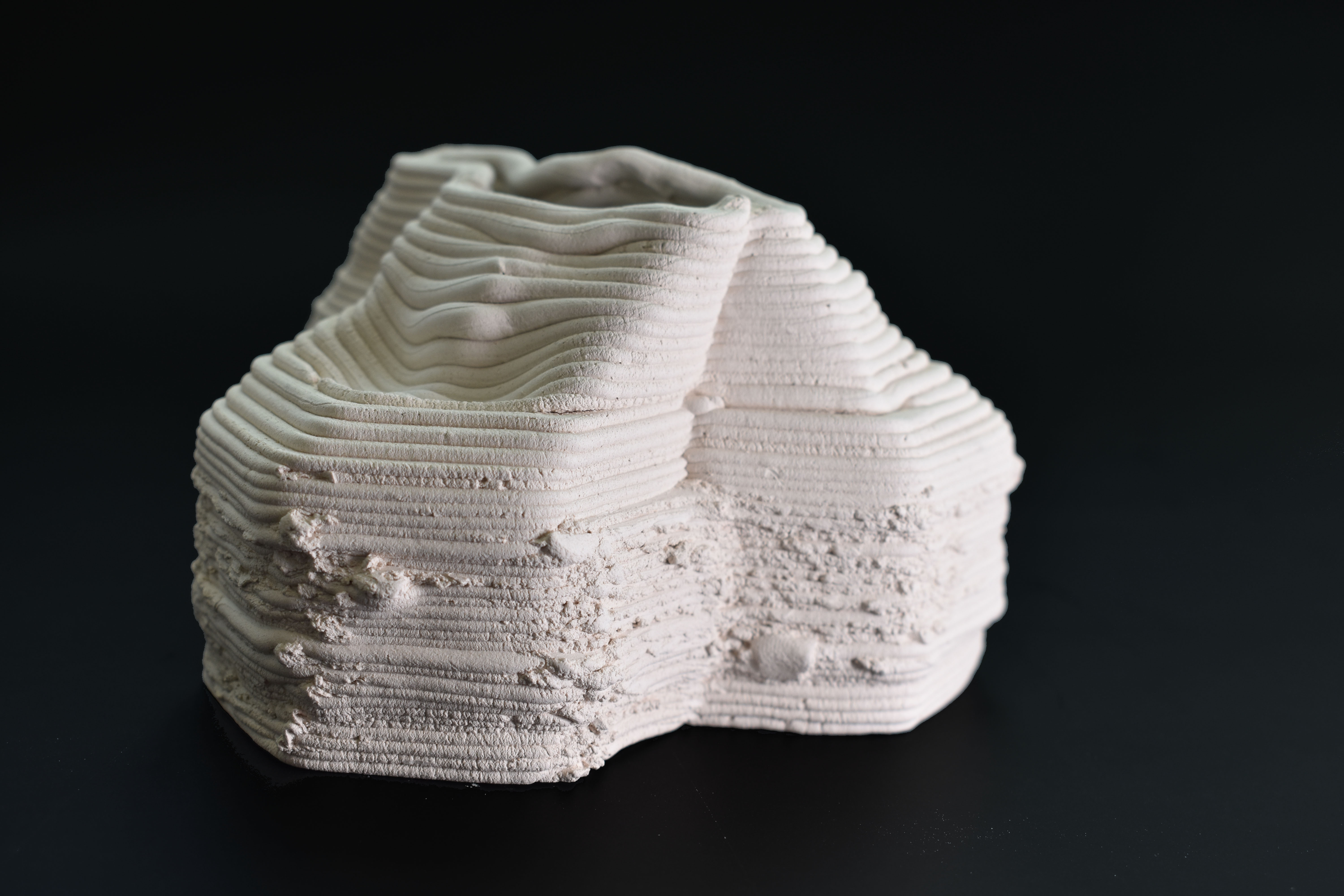

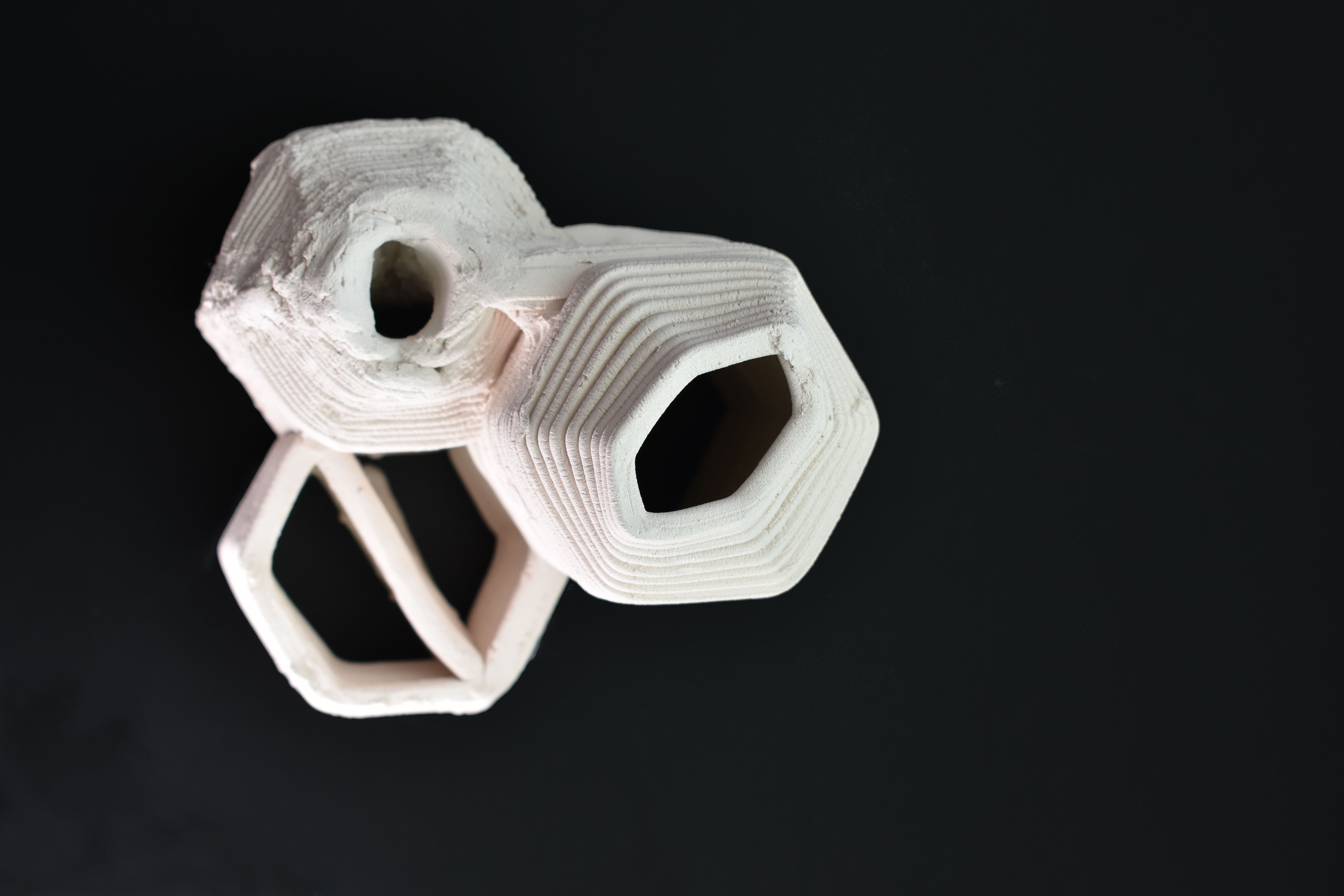

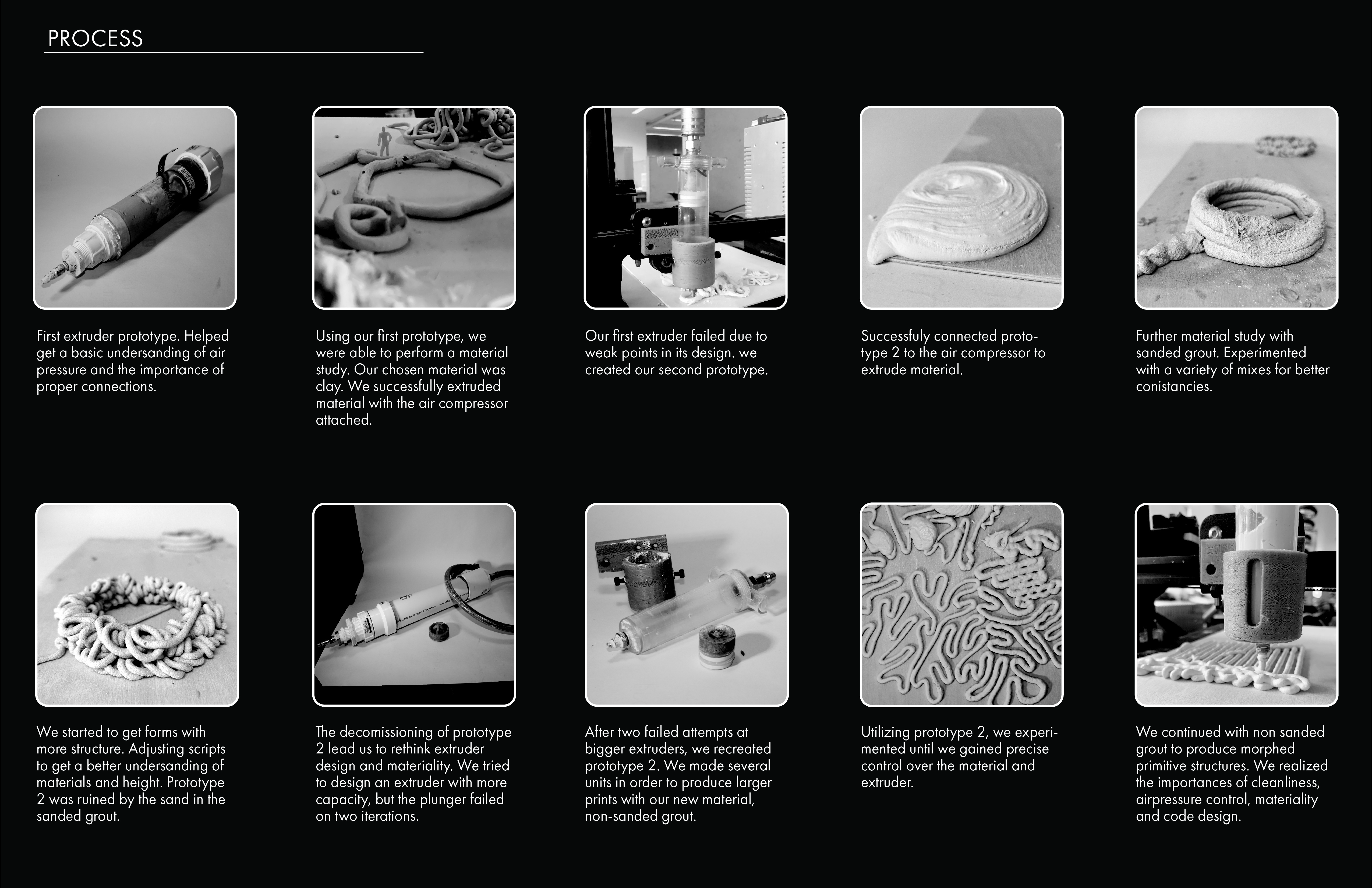

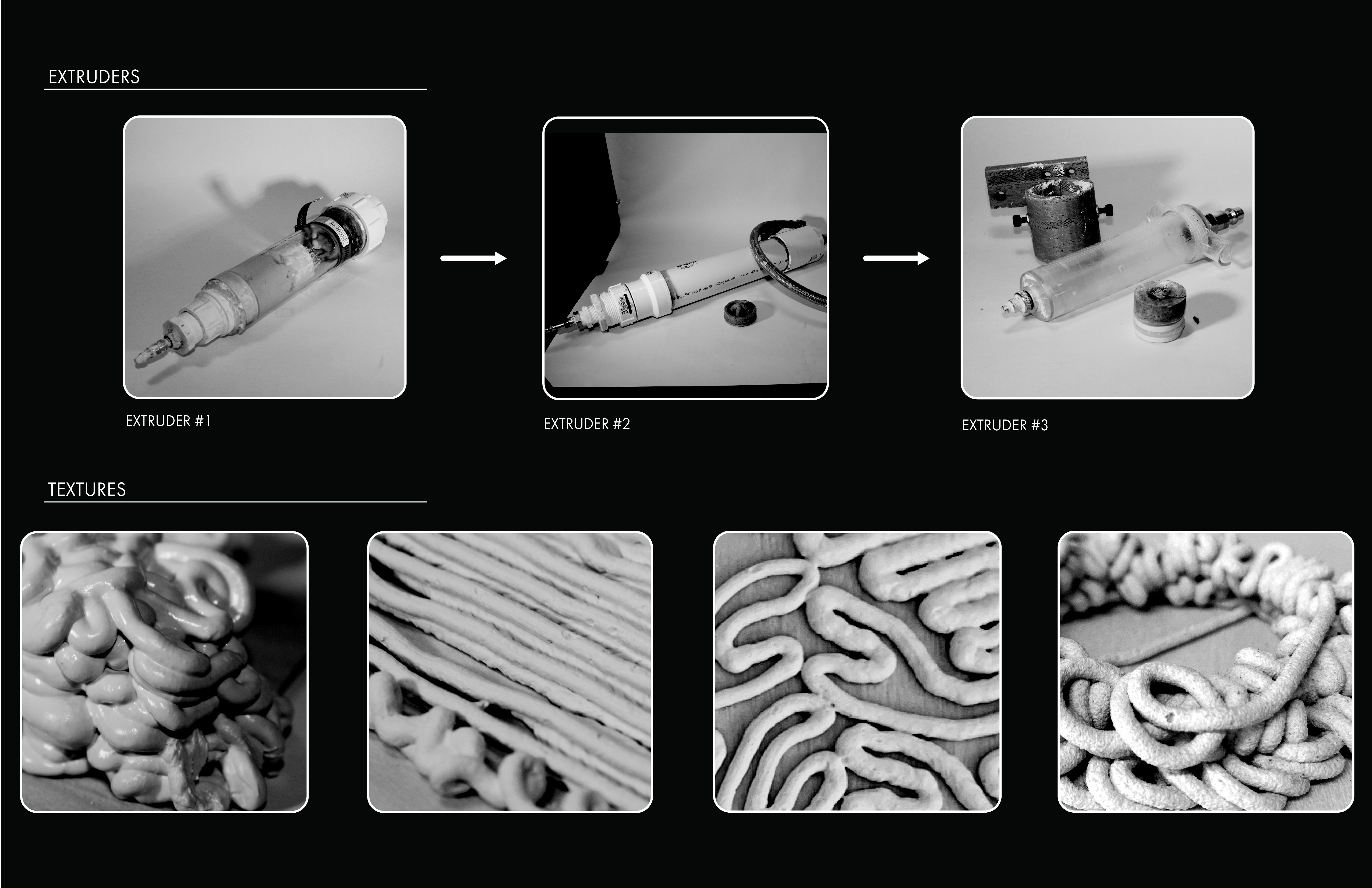

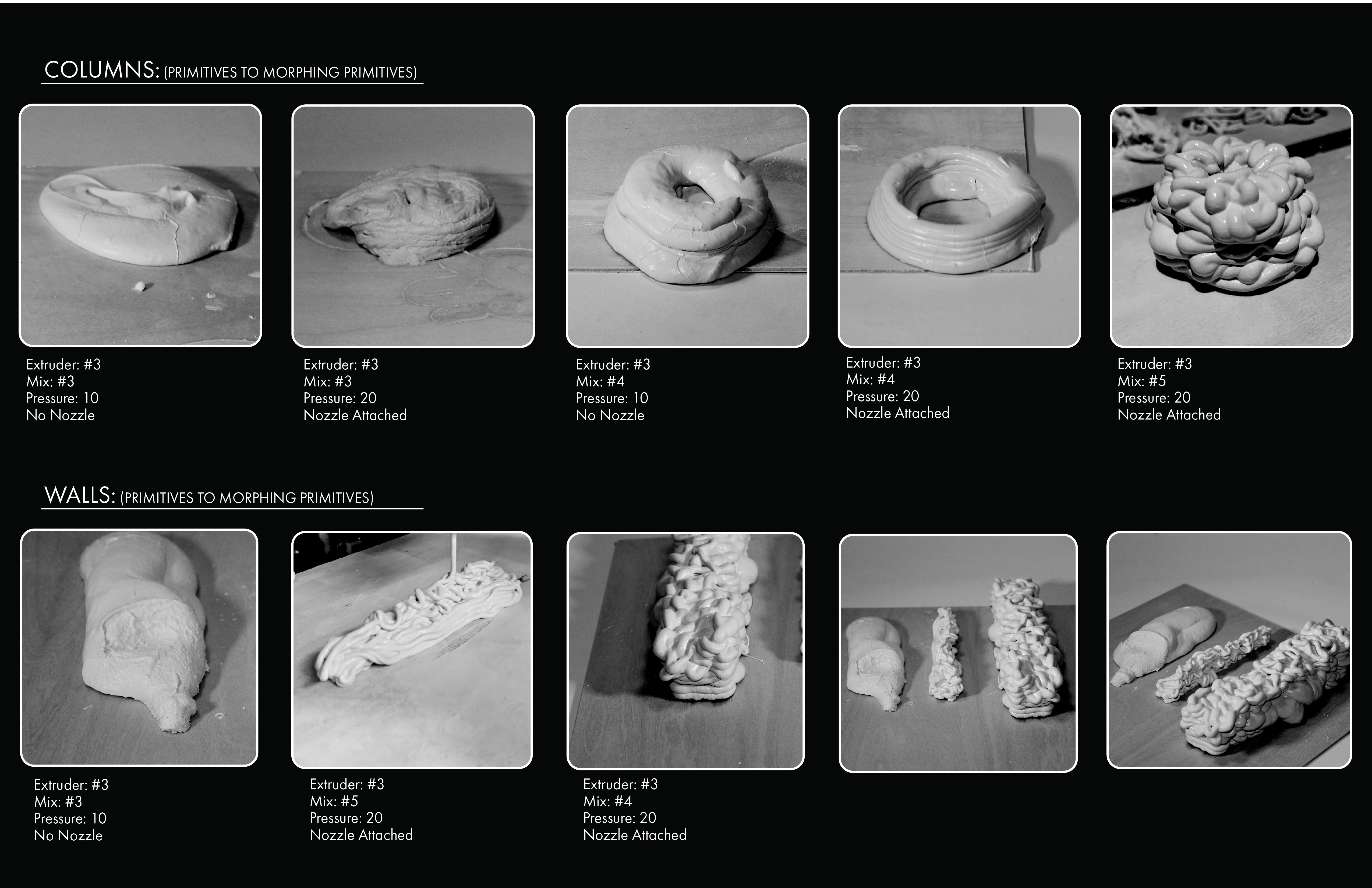

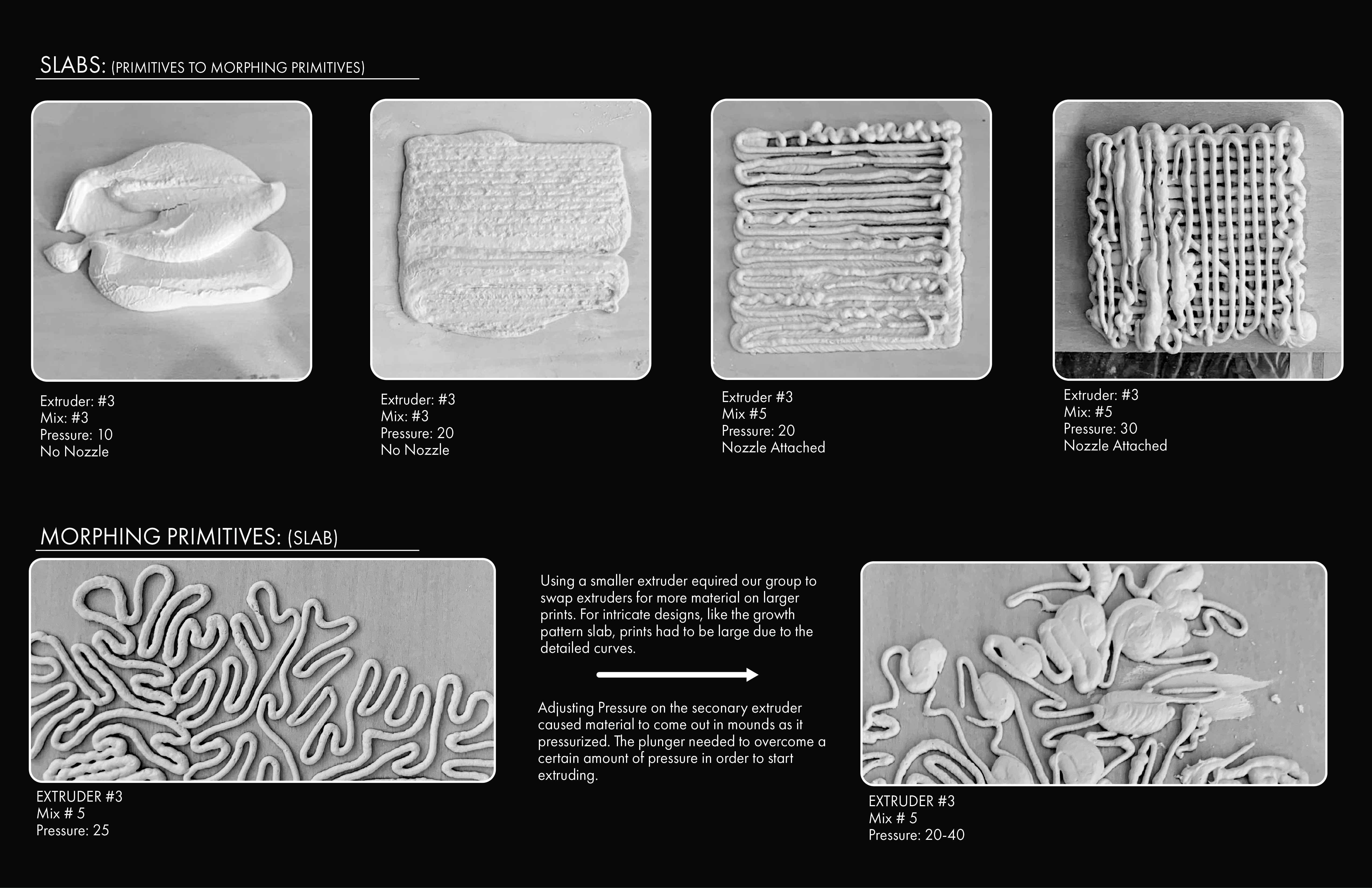

After gaining proficiency in plastic-based 3D printing, I took on the challenge of developing a pneumatic-powered extruder capable of utilizing ceramic material within the 3D printing process. This project proved instrumental in expanding my comprehension of diverse material properties, coding, and pushing the boundaries of 3D printing structures. I designed a pneumatic extruder that could be integrated with a modified Ender 3 printer. The journey involved multiple rounds of testing and prototyping, eventually leading to the successful creation of a functional extruder. My exploration of different material characteristics was pivotal in achieving the 3D printing of fundamental architectural elements. Below, you can witness my progress in printing columns, slabs, walls, and morphing primitives, demonstrating the evolution of my work.

Throughout my year-long research, I honed my extruder skills and transitioned to utilizing an ABB robotic arm for printing. This transition afforded me greater control over the printing process and allowed me to delve deeper into the realm of materiality, ultimately resulting in the creation of a diverse array of ceramic prints.