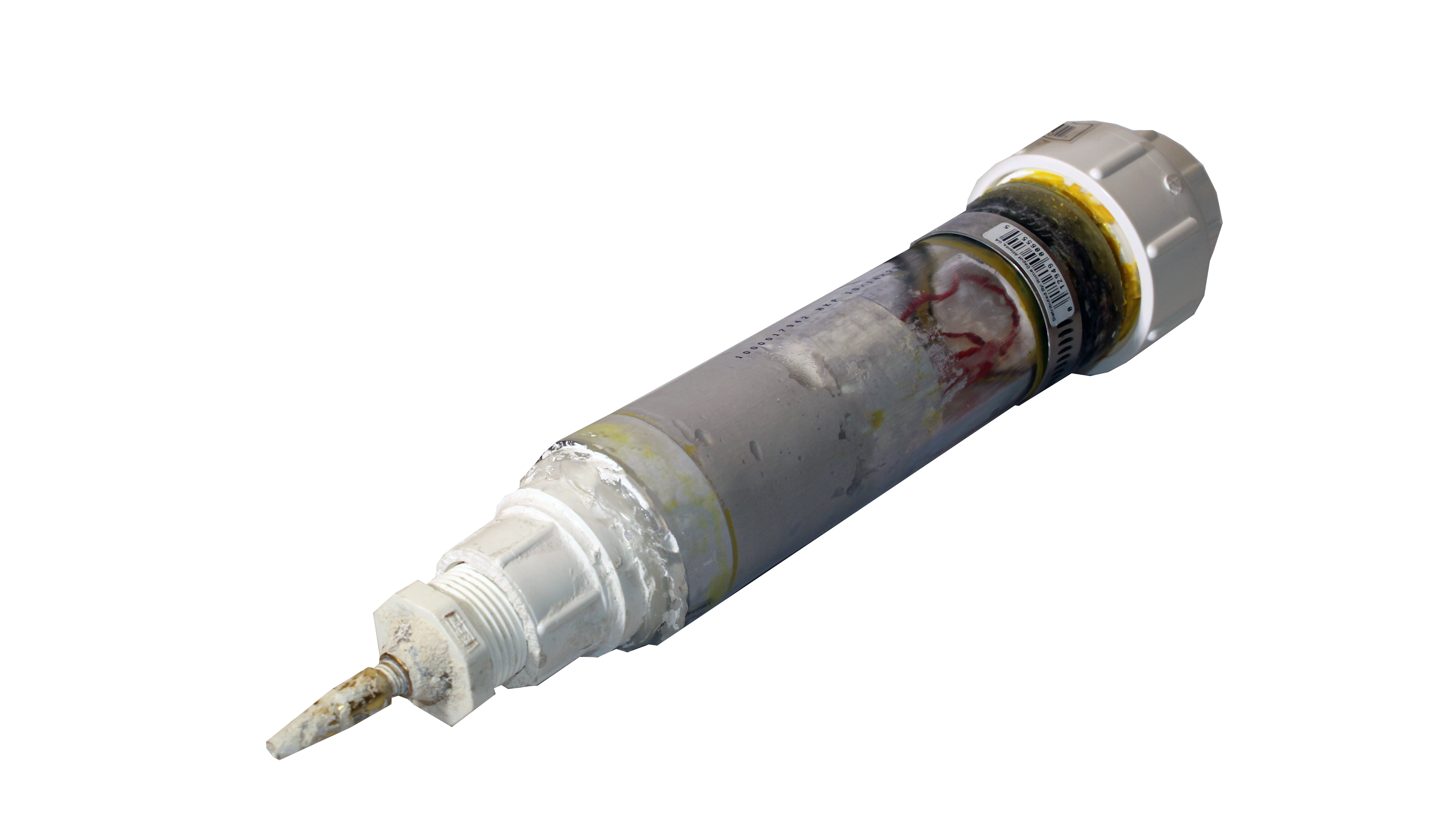

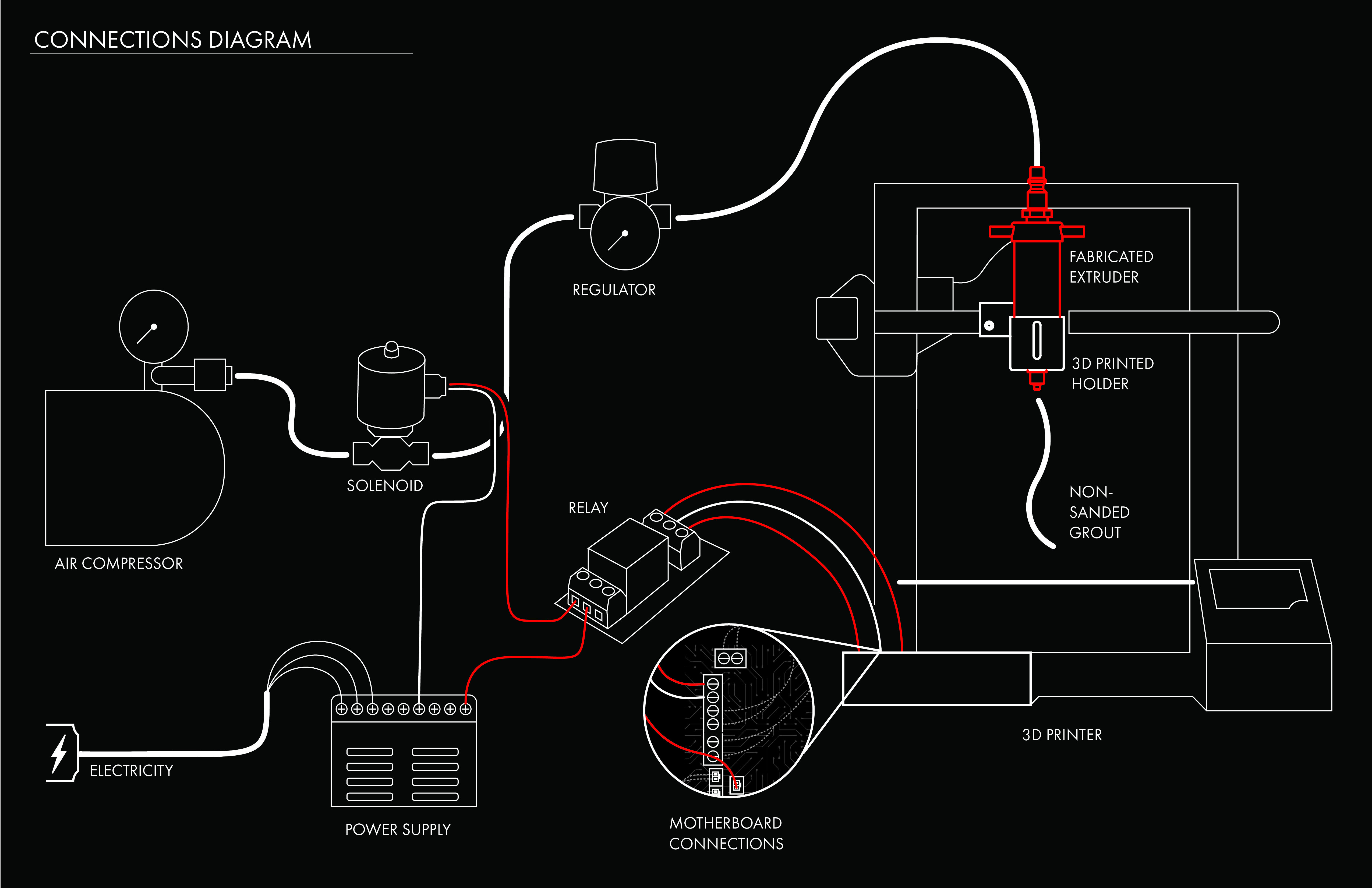

After gaining an understanding of printing plastics, I created a pneumatic powered extruder that would be able to utilize the 3D printer to print with ceramic material. I continued the research and design of my Pneumatic Extruder to create a finalized product. Inspired by 3D printing in architecture, my goal was to design a low-cost ceramic extruder targeting beginners and small architecture firms, aligning it with popular devices like the Creality Ender 3D printer and ABB robotic arm. I conducted comprehensive market research, examining existing competitors, pricing structures, and technological advancements. Rigorous testing on these platforms led to crucial modifications and attachment options. The final product design integrates safety features, including an air pressure release valve and quick release mechanisms. The device can accommodate a more substantial amount of material and enable precise printing with interchangeable nozzles. This project underscores my commitment to advancing architectural 3D printing technology.